Technology

Lab-Grown Diamond Coatings Combat Mineral Scale in Pipes

Research from Rice University has revealed that lab-grown diamond coatings can significantly reduce mineral scale build-up in industrial pipes, a major challenge affecting water and energy systems worldwide. This innovative solution offers a promising alternative to traditional methods, such as chemical additives and mechanical cleaning, which are often temporary and can have negative environmental impacts.

Understanding the Mineral Scaling Challenge

Mineral scaling occurs when deposits accumulate in pipes, much like limescale in a kettle, but on a much larger and more costly scale. These deposits can obstruct flow, strain equipment, and ultimately increase operational costs. According to Xiang Zhang, assistant research professor of materials science and nanoengineering and a lead author on the study, there is a pressing need for materials that can resist scale formation without requiring constant maintenance.

The breakthrough study identifies diamond as a viable coating material due to its renowned hardness, chemical stability, and capacity to withstand high temperatures. While previous research highlighted diamond’s effectiveness against biological fouling, its potential in minimizing mineral scale had not been thoroughly explored until now.

Innovative Coating Techniques

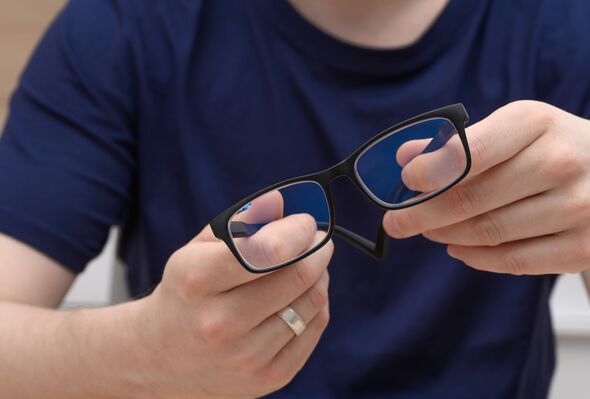

The researchers employed a technique known as microwave plasma chemical vapor deposition (MPCVD) to grow diamond films. This process involves feeding methane and hydrogen gases into a chamber, where microwave radiation energizes the gases into a plasma state. This reaction disassembles the gas molecules, allowing carbon atoms to settle onto a silicon wafer and form a dense diamond structure.

By applying post-growth treatments, the team was able to manipulate the surface chemistry of the diamond. One specific variant, the nitrogen-terminated diamond, demonstrated remarkable performance, accumulating over ten times less scale compared to diamonds treated with other gases such as oxygen, hydrogen, or fluorine. Microscopy revealed that while other surfaces developed thick layers of scale, the nitrogen-terminated diamond only showed scattered crystal clusters.

To further understand this behavior, molecular simulations indicated that nitrogen promotes the formation of a tightly bound layer of water molecules on the diamond’s surface. This layer serves as a barrier, making it difficult for mineral ions to adhere and initiate scaling.

The research team also applied this innovative chemistry to boron-doped diamond electrodes used in electrochemical systems. These electrodes collected approximately one-seventh as much scale without compromising their performance, showcasing the broad applicability of this technology.

According to Pulickel Ajayan, the Benjamin M. and Mary Greenwood Anderson Professor of Engineering at Rice University, the findings indicate that vapor-grown, cost-effective polycrystalline diamond films could serve as long-lasting anti-scaling materials. This technology holds potential across various industries, including water desalination and energy production, where mineral build-up poses significant challenges.

Jun Lou, the Karl F. Hasselmann Professor of Materials Science and Nanoengineering, emphasized the attractiveness of the scalable and versatile deposition process for multiple sectors. The comprehensive nature of this study was made possible due to advancements in technology that have improved the cost and availability of high-quality diamond films and reliable surface treatment methods.

This pioneering research underscores the potential of lab-grown diamond coatings as a sustainable solution to a longstanding industrial problem. The findings were published in the journal ACS Nano on November 22, 2025, and represent a significant step forward in the quest for efficient and environmentally friendly industrial practices.

-

Top Stories1 month ago

Top Stories1 month agoRachel Campos-Duffy Exits FOX Noticias; Andrea Linares Steps In

-

Top Stories1 week ago

Top Stories1 week agoPiper Rockelle Shatters Record with $2.3M First Day on OnlyFans

-

Top Stories6 days ago

Top Stories6 days agoMeta’s 2026 AI Policy Sparks Outrage Over Privacy Concerns

-

Sports5 days ago

Sports5 days agoLeon Goretzka Considers Barcelona Move as Transfer Window Approaches

-

Top Stories1 week ago

Top Stories1 week agoUrgent Update: Denver Fire Forces Mass Evacuations, 100+ Firefighters Battling Blaze

-

Top Stories1 week ago

Top Stories1 week agoOnlyFans Creator Lily Phillips Reconnects with Faith in Rebaptism

-

Entertainment5 days ago

Entertainment5 days agoTom Brady Signals Disinterest in Alix Earle Over Privacy Concerns

-

Top Stories7 days ago

Top Stories7 days agoOregon Pilot and Three Niece Die in Arizona Helicopter Crash

-

Health2 months ago

Health2 months agoTerry Bradshaw Updates Fans on Health After Absence from FOX NFL Sunday

-

Top Stories5 days ago

Top Stories5 days agoWarnock Joins Buddhist Monks on Urgent 2,300-Mile Peace Walk

-

Top Stories3 days ago

Top Stories3 days agoCBS Officially Renames Yellowstone Spin-off to Marshals

-

Sports3 days ago

Sports3 days agoSouth Carolina Faces Arkansas in Key Women’s Basketball Clash