Innovative Process Revolutionizes Rare Earth Element Recycling

A groundbreaking recycling process developed by researchers at Rice University significantly enhances the recovery of rare earth elements from electronic waste. This method, which employs rapid heating techniques, simplifies the extraction of elements crucial for manufacturing permanent magnets used in hard drives and electric vehicle (EV) motors. Rare earth elements, while not scarce in nature, are notoriously difficult and costly to produce due to their complex separation requirements.

The new process is described in a recent study published in the Proceedings of the National Academy of Sciences. According to the life-cycle analysis conducted by the research team led by James Tour, this innovative approach reduces the number of processing steps by one-third, lowers energy consumption by 87 percent, and minimizes greenhouse gas emissions by 84 percent compared to traditional methods.

Understanding the Challenges of Rare Earth Element Production

Rare earth elements play a vital role in various modern technologies, including lasers, electronics, and high-performance magnets. They are primarily found in mixed deposits and possess similar chemical properties, making their separation a complex and expensive process. Currently, China dominates the global market, controlling most of the supply and processing capacity of these essential materials. As a result, the United States relies heavily on imports for its rare earth magnets.

Tour emphasizes that the U.S. has abundant supplies of separated rare earth elements, primarily sourced from electronic waste. He noted, “The waste materials have 100 to 1,000 times higher concentrations than are found in ores.” This highlights the potential of urban mining as a solution to reduce reliance on foreign sources.

Flash Joule Heating: A Game-Changer in Recycling

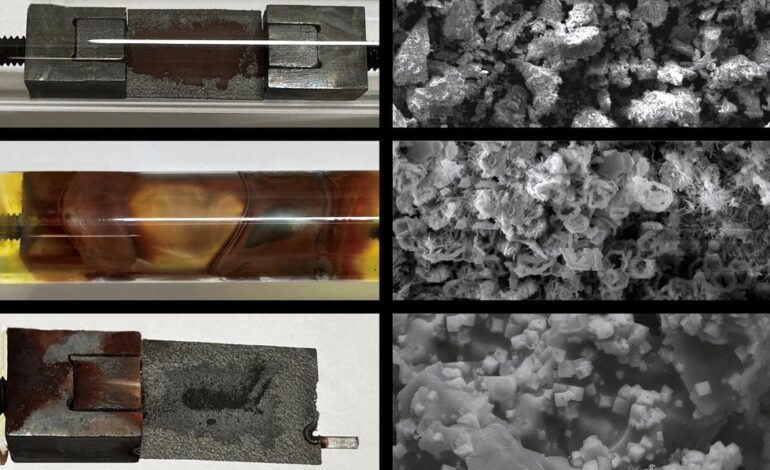

The innovative recycling technique utilizes a method known as flash joule heating. This process rapidly heats waste magnet material in the presence of chlorine gas, effectively separating valuable rare earth elements from other metals. Tour likens the setup to a toaster oven, where a heating element can achieve temperatures exceeding 10,000 Kelvin within seconds.

The process begins with demagnetized, ground-up waste placed on a specialized heating element made from carbon paper. The rapid heating allows the transition metals to react with chlorine gas at lower temperatures, producing transition metal chlorides that evaporate, leaving behind rare earth elements that are approximately 90 percent pure. So far, the method has been tested on two widely used rare earth magnet materials: samarium-cobalt and neodymium-iron-boron.

Tour explains that this advancement not only facilitates recycling but could also enhance the efficiency of magnet manufacturing. Traditional methods result in over 70 percent of the starting material being wasted when shaping neodymium-iron-boron magnets. By recovering these materials, the process could significantly reduce waste and improve sustainability in the industry.

The research team’s journey into this innovative process stems from their previous work on synthesizing graphene. In 2020, they demonstrated that graphene can be produced by rapidly heating carbon-based materials. This technology has since been commercialized through a spin-off company, Universal Matter, which utilizes flash joule heating to produce substantial quantities of graphene.

As the demand for rare earth elements continues to grow, this new recycling process could play a pivotal role in reshaping the landscape of resource recovery and reducing the environmental impact of traditional mining practices. By harnessing existing electronic waste, it offers a promising avenue for sustainable development in technology and manufacturing.