Innovative Process Enhances Manganese Ion Recovery from Wastewater

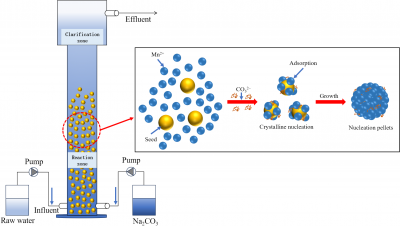

A recent study has unveiled a groundbreaking method for recovering manganese ions from hydrometallurgical tailings water. The Nucleation Crystallization Pelleting Process demonstrates not only high efficiency but also practical applicability, positioning it as a viable solution for addressing both resource wastage and environmental concerns.

The research highlights the potential of this innovative process to recover high concentrations of manganese ions, a critical element used in various industrial applications. By targeting hydrometallurgical tailings water, which often contains valuable minerals, the process aims to minimize the environmental impact associated with traditional mining and extraction methods.

Key Findings and Implications

The study emphasizes that implementing the nucleation crystallization pelleting process could substantially lower the ecological footprint of manganese extraction. By efficiently recovering manganese from waste streams, it offers a dual benefit: conserving natural resources while reducing the pollution generated by conventional mining operations.

The researchers conducted experiments that showcased the process’s ability to achieve a remarkable recovery rate, which could significantly enhance resource efficiency in the mining sector. As industries increasingly seek sustainable practices, the findings from this study could prompt a shift in how manganese and other minerals are sourced.

Future Prospects and Industry Impact

Looking ahead, the potential widespread adoption of this method could lead to a transformation in the hydrometallurgical sector. With resources becoming scarcer and environmental regulations tightening, technologies like the nucleation crystallization pelleting process represent a crucial step toward sustainable mineral recovery.

In conclusion, the advancements presented in this study not only reflect a significant scientific achievement but also underline the urgency for more sustainable practices in resource recovery. As industries grapple with the dual challenges of resource depletion and environmental responsibility, innovative solutions such as this could pave the way for a more sustainable future in mineral extraction.