ADCERAX Unveils High-Purity Alumina Tubes for Robotics Revolution

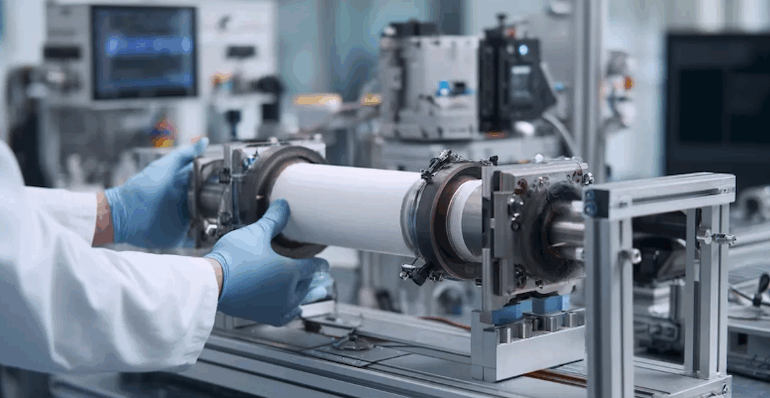

ADCERAX has launched a new generation of high-purity alumina ceramic tube technology, specifically designed to support the growing needs of industrial automation and robotics. This advanced material is engineered to perform reliably under extreme conditions, addressing the increasing demand for components that can withstand thermal and mechanical stress in automated systems.

As industrial applications evolve, robots are now operating in harsher environments, including industrial furnaces, precision thermal modules, and semiconductor handling. The new alumina tubes are built to function effectively at temperatures exceeding 1,500°C, while ensuring precise dimensional stability. This level of performance is critical in applications where both thermal management and structural integrity are paramount.

Innovative Features and Applications

ADCERAX’s alumina tube platform features a controlled microstructure that enhances dielectric insulation and long-term resistance to thermal cycling. Manufactured from high-purity Al2O3, these tubes exhibit low thermal expansion, excellent creep resistance, and minimal deformation under sustained heat loads. This makes them ideal for use in heating assemblies, tube-based sensors, furnace rails, and compact robotic mechanisms.

The demand for stable high-temperature components is rising across various sectors, including automated manufacturing, environmental systems, semiconductor processing, and scientific instrumentation. According to industry analysts, as automation increasingly integrates with AI-driven process control, the necessity for engineered ceramic components is expected to grow significantly.

Market Implications and Future Prospects

High-temperature materials are now recognized as essential for robotics functioning in challenging environments, particularly within the energy sector, advanced manufacturing, and high-throughput laboratory automation. An engineering representative from ADCERAX remarked, “Today’s automation systems require materials that remain stable under continuous thermal load while delivering mechanical reliability. Our new alumina tube line is specifically developed to meet these demands in robotics, sensors, and industrial heating applications.”

The new product line is manufactured with tight tolerances, allowing for custom geometries that support integration into specialized equipment platforms. This adaptability ensures compatibility with original equipment manufacturer (OEM) design requirements across multiple automation segments.

ADCERAX is a global supplier of engineered ceramic components that excel in high-temperature and high-precision environments. With a comprehensive product portfolio encompassing alumina, zirconia, silicon nitride, and silicon carbide, the company offers custom machining, engineering collaboration, and technical material solutions for industrial clients worldwide. For more information, visit the ADCERAX website.