Researchers Develop Advanced Continuum Robot Using VCM Mechanism

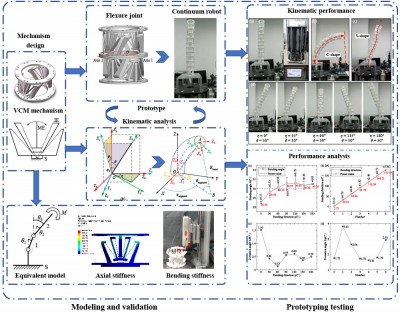

The field of robotics has taken a significant leap forward with the development of a new continuum robot designed by a team of researchers from **Beihang University** and the **Beijing Special Engineering Design and Research Institute**. This innovative robot utilizes a flexural virtual-center of motion (VCM) mechanism, addressing common limitations in traditional robotics that hinder performance in confined spaces.

Continuum robots are increasingly recognized for their unique adaptability and flexibility, making them ideal for applications in areas such as minimally invasive surgery, aviation inspection and repair, and tasks related to nuclear power. Their ability to navigate and manipulate within tight environments offers a distinct advantage in these critical fields.

Innovative Design Overcomes Traditional Limitations

The research team, consisting of **Guoxin LI**, **Jingjun YU**, **Yichao TANG**, **Jie PAN**, **Shengge CAO**, and **Xu PEI**, highlighted that conventional flexure mechanisms typically face challenges with limited bending angles. Additionally, rigid backbone continuum robots often encounter difficulties in assembly and operational accuracy. The new VCM mechanism can be manufactured as a single unit, eliminating the need for complex joint assembly, thus enhancing the overall functionality of continuum robots.

The study titled “Design and Modeling of Continuum Robot Based on Virtual-Center of Motion Mechanism” effectively demonstrates how this mechanism can significantly improve the performance of continuum robots. The design offers greater flexibility, allowing for wider ranges of motion and more precise control in various applications.

Implications for Future Robotics Applications

The implications of this research extend beyond academic interest. With the ability to maneuver in narrow and complex environments, the continuum robot could revolutionize procedures in healthcare, aviation, and nuclear sectors. For instance, in minimally invasive surgeries, the flexibility and precision of the robot could lead to reduced recovery times and improved patient outcomes.

The findings from this study represent a crucial advancement in robotic technology, particularly for industries that demand high levels of dexterity and precision. The collaborative effort from **Beihang University** and the **Beijing Special Engineering Design and Research Institute** emphasizes the importance of innovative engineering solutions in addressing the challenges of modern robotics.

As the technology progresses, continued research and development will likely bring forth even more sophisticated robotic systems capable of transforming how we approach complex tasks across various sectors. The future of continuum robots powered by advanced mechanisms like the flexural VCM looks promising, setting the stage for new breakthroughs in robotics.