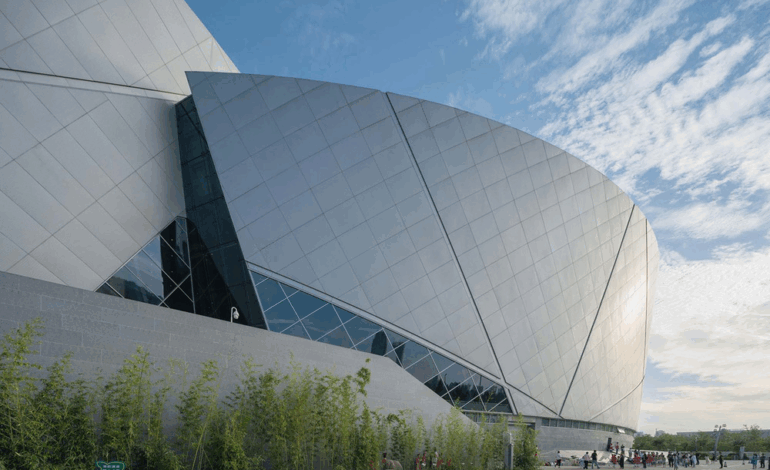

Aluminum Facade Panels Enhance Energy Efficiency and Sustainability

Aluminum facade panels are increasingly recognized for their role in improving energy efficiency and enhancing the sustainability of buildings. Their lightweight and robust characteristics not only contribute to the aesthetic appeal of modern architecture but also provide substantial benefits in terms of insulation and thermal management.

Advantages of Aluminum Facade Panels

One of the most significant benefits of aluminum is its high recyclability. Unlike other materials, recycled aluminum maintains its quality and can be reused indefinitely. This process significantly reduces energy consumption during production, cuts carbon emissions, and supports sustainable building practices. According to industry sources, using recycled aluminum saves up to **95%** of the energy required to produce new aluminum, making it an environmentally friendly choice for contemporary architecture.

Aluminum’s durability and strength are also noteworthy. It is resistant to corrosion and rust, which translates to lower maintenance costs and prolonged structural integrity. These qualities make aluminum ideal for high-performance facade panels that endure harsh weather conditions while maintaining their appearance.

Another critical feature of aluminum facade panels is their energy efficiency. The reflective properties of aluminum help manage heat absorption, reducing thermal gain during warmer months. When combined with modern insulation materials, these panels can significantly enhance a building’s energy performance, aiding in achieving certifications such as **LEED** or **BREEAM**.

Impact on Building Performance

The integration of aluminum facade panels contributes to a building’s overall thermal barrier, effectively reducing heat loss in winter and heat gain in summer. This integration not only supports energy savings but also leads to enhanced indoor comfort. By maintaining stable indoor temperatures, aluminum panels can decrease reliance on heating, ventilation, and air conditioning (HVAC) systems, ultimately leading to lower energy bills and a reduced carbon footprint.

Moreover, the design flexibility of aluminum allows architects to create visually appealing structures without compromising on functionality. Perforated aluminum panels, for instance, can optimize daylighting and natural ventilation, further reducing the need for artificial lighting and mechanical cooling systems. This passive cooling method can lead to significant energy savings over time.

The long-term performance of aluminum facade panels is another advantage worth mentioning. They retain their structural integrity and insulation properties, ensuring consistent energy efficiency throughout their lifespan. This durability translates to lower maintenance and replacement costs compared to other facade materials.

Incorporating aluminum facade panels into building designs not only enhances energy efficiency but also supports sustainable construction practices. By utilizing environmentally friendly insulation materials, these panels can help achieve green building certifications, ultimately increasing property value while promoting sustainability.

The financial and environmental benefits of aluminum facade panels are compelling. Although the initial costs may be higher than some alternatives, the long lifespan, low maintenance requirements, and energy savings make them a cost-effective choice in the long run. Their ability to minimize greenhouse gas emissions and promote a circular economy in construction further solidifies their importance in modern architecture.

In summary, aluminum facade panels stand out as a practical solution for enhancing energy efficiency and sustainability in building construction. They offer a combination of durability, aesthetic appeal, and environmental benefits that support contemporary architectural practices. As the demand for sustainable and energy-efficient buildings continues to grow, aluminum facade panels will play a crucial role in shaping the future of the construction industry.